5 Coastal Roof Edge Flashing Alternatives That Defeat Salt Air Corrosion

Living near the coast means your home faces unique challenges from salt air, high winds, and moisture that can wreak havoc on traditional roof edge flashing. Standard metal flashings often corrode quickly in coastal environments, leading to water damage and expensive repairs.

You don’t have to settle for premature replacements or ongoing maintenance battles. Modern alternatives specifically designed for coastal conditions offer superior durability and protection against the harsh seaside elements while maintaining your home’s aesthetic appeal.

Disclosure: As an Amazon Associate, this site earns from qualifying purchases. Thank you!

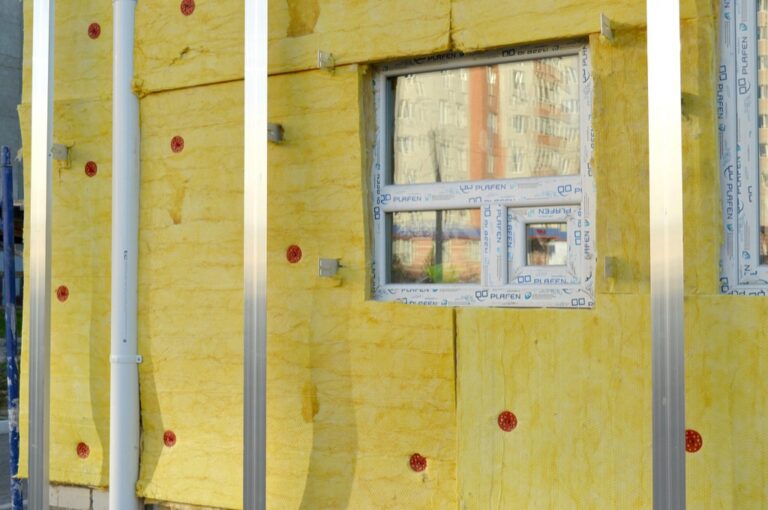

Understanding the Unique Challenges of Coastal Roofing

Why Traditional Flashing Falls Short in Coastal Areas

Traditional metal flashings fail prematurely in coastal environments due to constant salt spray exposure. The combination of salt, moisture, and high winds accelerates corrosion, causing edge metals to deteriorate within 3-5 years instead of the typical 15-20 year lifespan. This rapid breakdown creates entry points for water, leading to sheathing damage and interior leaks that compromise your roof’s structural integrity.

The Critical Role of Corrosion Resistance in Seaside Environments

Corrosion resistance isn’t just desirable for coastal roofing—it’s essential for survival. Salt-laden air can penetrate microscopic imperfections in standard flashing materials, initiating corrosion from within. Even stainless steel and galvanized options eventually succumb to the relentless coastal conditions, making specialized marine-grade alternatives necessary to protect your roof’s edges from the persistent assault of salt, moisture, and UV exposure.

Aluminum Flashing Systems: Lightweight Corrosion Fighters

Aluminum flashing offers a strategic advantage for coastal homes with its natural resistance to salt-air corrosion. Unlike traditional galvanized options, quality aluminum systems can withstand coastal conditions for 15-20 years while providing exceptional protection against water intrusion.

Top Aluminum Products for Coastal Applications

Marine-grade aluminum flashing (6000 series) delivers superior performance with its thicker 0.032-0.040 inch profiles compared to standard varieties. Powder-coated aluminum drip edges provide enhanced durability with their protective finish that prevents pitting. Kynar-finished aluminum step flashing systems offer premium protection with their advanced coating technology that maintains integrity even against constant salt spray.

Installation Best Practices for Maximum Longevity

Always use aluminum-compatible fasteners to prevent galvanic corrosion that would otherwise create premature failure points. Apply polyurethane sealant at joints rather than silicone for stronger coastal adhesion and UV resistance. Install with slightly wider overlaps (minimum 4 inches) than standard installations to account for coastal wind-driven rain. Create proper drainage channels to prevent standing water that accelerates corrosion in even resistant materials.

Stainless Steel Alternatives: Premium Protection for Harsh Environments

When standard flashings fail in coastal settings, stainless steel alternatives offer exceptional durability against the harshest elements. These premium options provide superior protection while maintaining aesthetic appeal for your seaside home.

Marine-Grade Stainless Steel Options

Marine-grade 316 stainless steel flashing delivers unmatched corrosion resistance in salt-heavy environments. Unlike standard 304 stainless, this upgraded alloy contains molybdenum, which prevents pitting and extends lifespan to 30+ years even with direct saltwater exposure. Look for options with pre-formed corners and seamless designs that eliminate weak points where corrosion typically begins.

Cost-Benefit Analysis of Stainless Steel Investments

Marine-grade stainless steel flashings typically cost 2-3 times more than standard alternatives, averaging $12-18 per linear foot installed. However, this premium pays for itself through virtually eliminated replacement costs over decades. The true value emerges when comparing lifetime costs – while aluminum might require replacement every 15 years, quality stainless installations often outlast the roof itself, saving $3,000-5,000 in future labor and materials.

Copper Flashing: Beautiful Aging with Superior Weather Resistance

Copper flashing offers coastal homeowners a premium solution that combines exceptional durability with distinctive aesthetic appeal. Unlike standard metals, copper doesn’t corrode in salt-laden environments—instead, it develops a protective patina that enhances its weather resistance over time. This natural aging process creates a stunning verdigris finish that complements many architectural styles while providing superior protection against coastal elements.

Self-Healing Properties of Copper in Coastal Settings

Copper’s remarkable self-healing ability makes it ideal for harsh coastal environments. When scratched or damaged, copper forms a protective patina—copper carbonate—that seals the exposed area within days. This natural chemical reaction prevents further deterioration and eliminates weak points where moisture could penetrate, effectively extending the flashing’s lifespan to 50+ years even in salt-spray conditions.

Maintaining Copper Flashing Systems Over Time

Copper flashing requires minimal maintenance compared to other materials. Annual inspections should focus on clearing debris from valleys and ensuring fasteners remain secure. If you prefer to preserve copper’s original shine, apply a marine-grade copper sealant every 2-3 years. Otherwise, simply let nature take its course—the developing patina actually strengthens the flashing’s protective properties while creating a distinctive coastal aesthetic.

Advanced Polymer and Composite Solutions: The Modern Approach

Innovative polymer and composite materials represent the cutting edge of coastal roof edge flashing technology, offering superior corrosion resistance while maintaining structural integrity against harsh marine conditions.

Flexible PVC and TPO Flashing Systems

Flexible PVC and TPO flashing systems provide exceptional salt resistance with zero corrosion potential. These materials can flex with building movement, preventing cracks during thermal expansion. Unlike metals, these systems form watertight seals through heat-welding, eliminating the need for sealants that deteriorate in coastal environments. Modern formulations include UV stabilizers that prevent degradation for 20+ years of protection.

Emerging Hybrid Materials Designed for Salt Exposure

New hybrid composites combine fiberglass reinforcement with specialized polymers specifically engineered for coastal exposure. These materials maintain structural integrity after decades of salt spray contact while weighing 70% less than traditional metal alternatives. Advanced manufacturing techniques create seamless edge profiles that eliminate water entry points. Installation requires specialized fasteners but results in near-permanent protection against even the harshest oceanfront conditions.

Making the Right Choice for Your Coastal Roof Protection

Protecting your coastal home from the harsh marine environment doesn’t have to mean frequent replacements or ongoing maintenance headaches. The alternatives we’ve explored—from aluminum and stainless steel to copper and advanced polymers—each offer superior performance compared to traditional flashings.

Your choice ultimately depends on your specific needs and budget. Aluminum provides excellent value while stainless steel delivers exceptional longevity. Copper offers unmatched aesthetic appeal with outstanding durability and polymer systems bring cutting-edge protection against salt air.

Remember that proper installation is just as important as material selection. Work with contractors experienced in coastal applications and use compatible fasteners and sealants for your chosen system. With the right flashing alternative your roof can withstand coastal conditions for decades rather than years saving you significant money and stress.

Frequently Asked Questions

Why do metal flashings fail prematurely in coastal areas?

Metal flashings fail prematurely in coastal areas due to constant exposure to salt spray, high winds, and moisture. These elements accelerate corrosion, causing flashings to deteriorate within 3-5 years instead of the typical 15-20 years. The breakdown creates entry points for water, leading to sheathing damage and interior leaks that compromise your roof’s structural integrity.

What is the best flashing material for coastal homes?

Marine-grade 316 stainless steel offers unmatched corrosion resistance with a lifespan exceeding 30 years. Aluminum flashing systems provide excellent salt-air resistance for 15-20 years. Copper creates a protective patina and can last over 50 years. Advanced polymers like PVC and TPO offer superior corrosion resistance with zero corrosion potential. The best choice depends on your budget and specific coastal conditions.

How long do aluminum flashing systems typically last in coastal environments?

Quality aluminum flashing systems typically last 15-20 years in coastal environments when properly installed. They provide natural resistance to salt-air corrosion while being lightweight and effective. For maximum durability, look for marine-grade aluminum flashing and powder-coated aluminum drip edges specifically designed for coastal applications.

Are stainless steel flashings worth the higher cost for coastal homes?

Yes, stainless steel flashings are worth the investment for coastal homes. While more expensive upfront, marine-grade 316 stainless steel can last over 30 years without deterioration, often outlasting the roof itself. This longevity eliminates multiple replacement cycles required with standard materials, providing substantial long-term savings and continuous protection against water intrusion.

What makes copper flashing ideal for coastal properties?

Copper flashing combines exceptional durability with aesthetic appeal for coastal properties. Unlike standard metals, copper doesn’t corrode in salt environments but develops a protective patina that enhances weather resistance. It features self-healing properties, forming a protective layer when scratched. With a lifespan exceeding 50 years and minimal maintenance requirements, copper provides lasting protection while developing a distinctive coastal aesthetic.

What are the advantages of polymer flashing systems in coastal areas?

Polymer flashing systems offer superior corrosion resistance with zero corrosion potential. These flexible PVC and TPO systems can move with building expansion, preventing cracks during thermal changes. They create watertight seals through heat-welding, eliminating the need for deterioration-prone sealants. Modern formulations include UV stabilizers for 20+ years of protection, making them ideal for harsh coastal environments.

What installation practices maximize flashing longevity in coastal regions?

To maximize flashing longevity in coastal regions, use compatible fasteners (aluminum or stainless steel) with your flashing material, apply polyurethane sealant for joints, create wider overlaps (minimum 4 inches) to accommodate wind-driven rain, and design proper drainage channels to prevent standing water. These best practices significantly extend the performance of your roofing system against harsh coastal conditions.

How often should coastal roof flashings be inspected?

Coastal roof flashings should be inspected at least twice annually—ideally before and after storm season. Look for signs of corrosion, loose fasteners, sealant deterioration, and water staining in the attic. After major storms, conduct additional inspections for wind damage. Prompt identification of minor issues prevents costly structural damage and extends the life of your roofing system.