5 Solar Roof Attachment Methods That Protect Your Warranty

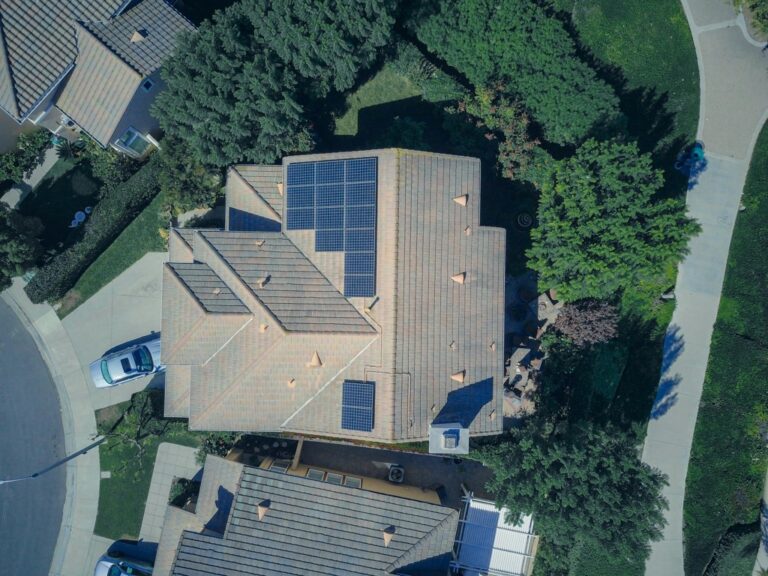

Looking to install solar panels but concerned about drilling into your roof? Traditional solar mounting methods often require penetrating your roof’s surface, which can lead to potential leaks and damage over time. Understanding the alternatives can save you thousands in future repairs while still harnessing clean energy.

Modern solar installation has evolved far beyond the standard penetrating mounts, offering innovative solutions that protect your roof’s integrity. These alternative attachment methods provide the security you need without compromising your roof’s waterproof barrier. You’ll discover options that work with virtually any roof type, from metal to tile, flat to steep-pitched.

Disclosure: As an Amazon Associate, this site earns from qualifying purchases. Thank you!

1. Ballasted Racking Systems: A Non-Penetrating Solution

Ballasted racking systems offer a revolutionary approach to solar panel installation that completely eliminates the need for roof penetrations. These systems use weight to secure solar arrays to your roof rather than traditional drilling and mounting methods.

How Ballasted Racking Systems Work

Ballasted systems rely on heavy concrete blocks or pavers (typically weighing 20-30 pounds each) positioned strategically throughout the solar array to secure panels against wind uplift. The solar modules sit on specialized frames that distribute weight evenly across your roof surface. This weight-based anchoring method creates a stable foundation that resists movement from wind and weather without a single screw penetrating your roofing membrane.

Ideal Roof Types for Ballasted Systems

Flat or low-slope commercial roofs (typically with pitches under 5 degrees) are perfect candidates for ballasted installations. These systems work exceptionally well on EPDM, TPO, or PVC membrane roofs common in commercial buildings. They’re also suitable for built-up roofs (BUR) and modified bitumen surfaces with adequate load-bearing capacity. Ballasted systems aren’t recommended for steep-pitched residential roofs where gravity would compromise the stability of the array.

Pros and Cons of Ballasted Racking

The primary advantage of ballasted systems is their preservation of roof warranty since they don’t create potential leak points through penetrations. Installation costs are typically 15-20% lower due to reduced labor hours and specialized flashing materials. However, these systems add significant weight (4-6 pounds per square foot) to your roof structure, potentially requiring engineering assessment before installation. They’re also limited to flat or low-slope applications and may require additional ballast in high-wind zones, further increasing the roof load.

2. Rail-Less Direct Mounting: Streamlining the Installation Process

Rail-less direct mounting systems represent a significant evolution in solar installation technology, offering a sleeker, more streamlined approach compared to traditional racking methods. This innovative technique attaches solar panels directly to your roof without the need for continuous rails, reducing both material costs and installation time.

Key Components of Rail-Less Systems

Rail-less systems utilize specialized brackets or mounts that attach directly to your roof’s structural members. These mounts typically include flashing components that integrate with existing roofing materials to maintain waterproofing integrity. Individual mounting points connect to panel frames using clamps, creating a distributed mounting system that evenly spreads the load across your roof structure.

Installation Efficiency and Cost Benefits

You’ll see substantial installation time savings with rail-less systemsâoften 30-40% faster than traditional rail-based setups. Material costs decrease by eliminating lengthy aluminum rails, reducing shipping expenses and material waste. The simplified design requires fewer components, translating to labor savings of up to $0.15 per watt for residential installations while creating a lower-profile, more aesthetically pleasing appearance.

Limitations and Considerations

Rail-less systems may not be suitable for all roof types, particularly those with irregular framing or deteriorating structures. You’ll need precise knowledge of rafter or truss locations for proper attachment, often requiring additional planning and measuring time. While offering excellent curb appeal, these systems sometimes provide less flexibility for accommodating complex roof geometries compared to traditional rail-based systems.

3. Shared Rail Mounting: Maximizing Efficiency with Fewer Attachments

Understanding Shared Rail Technology

Shared rail systems use a single rail to support the edges of four adjacent solar panels, effectively cutting the number of rails needed by up to 50%. Unlike traditional racking where each panel row requires two dedicated rails, shared rail mounting creates a grid pattern where rails serve multiple panels simultaneously. This ingenious design significantly reduces material costs while maintaining structural integrity.

Performance Benefits and Structural Advantages

Shared rail systems reduce roof penetrations by 25-40% compared to standard mounting methods, minimizing potential leak points. The integrated design distributes weight more evenly across your roof structure, reducing stress on individual attachment points. Additionally, these systems typically offer superior wind resistance ratings (often exceeding 120 mph) while using fewer components, making them both stronger and more cost-effective for larger installations.

Best Applications for Shared Rail Systems

Shared rail mounting excels on asphalt shingle and metal roofs with consistent rafter spacing. It’s particularly valuable for large residential and commercial installations where material efficiency translates to significant cost savings. The system works best on roofs with pitches between 15-45 degrees and offers exceptional performance in high-wind regions where structural integrity is paramount. However, it’s less suitable for complex roof designs with multiple obstructions.

4. Standing Seam Metal Roof Clamps: Preserving Roof Integrity

Standing seam metal roof clamps offer an elegant solution for solar installations on metal roofs, completely eliminating the need for penetrations while maintaining the structural integrity of your roofing system.

How Seam Clamps Attach Without Penetration

Standing seam clamps work by gripping the raised seams of metal roofs with mechanical pressure. These specialized clamps feature set screws that tighten against the seam, creating a secure attachment point without puncturing the metal surface. The solar mounting hardware then attaches directly to these clamps, distributing weight evenly across the roof structure while preserving the waterproof barrier.

Compatibility with Different Metal Roof Types

Not all metal roofs work with standard seam clamps. Snap-lock profiles, mechanical seams, and bulb seams each require specific clamp designs engineered for their unique profiles. Most clamps accommodate seam widths between 0.5-1.5 inches, but custom solutions exist for specialty profiles. Always verify your specific metal roof type and seam dimensions before selecting clamps to ensure proper fit and load capacity.

Long-Term Performance Considerations

Quality metal roof clamps typically last 25+ years, matching the lifespan of your solar system. Look for clamps made from aluminum or stainless steel with proper isolation materials to prevent galvanic corrosion between dissimilar metals. While installation costs may be 15-20% higher than penetrating methods, you’ll avoid potential leak repairs and maintain your roof warranty. Regular inspections ensure clamps remain properly torqued, especially in areas with extreme temperature fluctuations.

5. Solar Shingles and Integrated Systems: The Seamless Alternative

How Integrated Solar Differs from Traditional Panels

Solar shingles replace conventional roofing materials while generating electricity, creating a seamless roof surface rather than mounting panels above it. You’ll notice integrated systems blend completely with your roof’s aesthetic, functioning as both weatherproofing and power generation simultaneously. Unlike bulky traditional panels, these systems become part of your roof’s structure, eliminating the visual disruption of standard solar arrays.

Installation Process and Requirements

You’ll need a complete roof replacement or new construction to install solar shingles properly. The installation combines roofing and electrical work, requiring specialized contractors familiar with both disciplines. Your roof must have adequate sun exposure and appropriate pitch (typically 15-40 degrees) for optimal energy production. Most systems connect directly to your home’s electrical panel through interior wiring pathways, avoiding external conduit runs.

Cost Analysis and ROI Comparison

You’ll initially pay 25-30% more for solar shingles compared to traditional panels plus conventional roofing. This premium typically ranges from $21-25 per square foot versus $15-18 for separate systems. However, your ROI calculation should factor in saved roofing material costs, potential insurance premium reductions, and higher property values. Most homeowners recoup their investment within 12-15 years through energy savings, compared to 8-10 years for traditional panels.

Conclusion: Selecting the Right Alternative Attachment Method for Your Project

Choosing the right attachment method for your solar installation depends on your specific roof type budget and long-term goals. Ballasted systems offer stability for flat roofs while rail-less mounts provide streamlined aesthetics. Shared rail systems maximize efficiency and standing seam clamps preserve metal roof integrity without penetrations.

For complete roof transformations solar shingles deliver a seamless appearance despite higher upfront costs. These innovative alternatives protect your roof warranty reduce leak risks and often decrease installation time.

Before making your decision consult with a qualified solar installer who can assess your roof structure and recommend the most suitable non-penetrating method for your home. With these alternative techniques you can confidently embrace solar energy while maintaining your roof’s structural integrity for years to come.

Frequently Asked Questions

What are non-penetrating solar panel installation methods?

Non-penetrating solar panel installation methods are techniques that secure solar panels to roofs without drilling holes. These include ballasted racking systems, rail-less direct mounting, shared rail systems, standing seam metal roof clamps, and solar shingles. These methods preserve roof integrity, maintain waterproofing, and often keep roof warranties intact while still providing stable solar panel installations.

How does a ballasted racking system work?

A ballasted racking system uses heavy concrete blocks or pavers to secure solar panels against wind uplift instead of penetrating the roof. The weight of these ballasts keeps the solar array firmly in place. This system is ideal for flat or low-slope commercial roofs with materials like EPDM, TPO, or PVC. While it preserves roof warranties and reduces installation costs, it adds significant weight to the roof structure.

Are rail-less mounting systems more cost-effective?

Yes, rail-less mounting systems are generally more cost-effective. They attach solar panels directly to the roof without continuous rails, reducing material costs and installation time by 30-40% compared to traditional methods. These systems use specialized brackets that integrate with existing roofing materials to maintain waterproofing integrity, though they require precise knowledge of rafter locations for proper installation.

What are the benefits of shared rail mounting systems?

Shared rail mounting systems reduce roof penetrations by 25-40% compared to standard methods by using a single rail to support the edges of four adjacent panels. This design minimizes potential leak points, distributes weight more evenly across the roof, and cuts material costs. They offer superior wind resistance and work best on asphalt shingle and metal roofs with consistent rafter spacing and pitches between 15-45 degrees.

How do standing seam metal roof clamps work?

Standing seam metal roof clamps grip the raised seams of metal roofs using mechanical pressure, securing solar panels without puncturing the metal surface. Different clamp designs accommodate various seam profiles, preserving the roof’s structural integrity and warranty. While installation costs may be higher than penetrating methods, they eliminate leak risks associated with roof penetrations. Regular inspections ensure the clamps remain properly torqued.

What are solar shingles and how do they differ from traditional panels?

Solar shingles are roofing materials that generate electricity, replacing conventional roofing while creating a unified, aesthetically pleasing roof surface. Unlike traditional panels that mount on top of existing roofs, solar shingles require complete roof replacement or new construction and specialized contractors. Though initially 25-30% more expensive than traditional panels, homeowners typically recoup their investment within 12-15 years through energy savings.

Which non-penetrating method is best for flat commercial roofs?

Ballasted racking systems are ideal for flat commercial roofs. These systems use weighted blocks to secure solar arrays without penetrating the membrane, preserving waterproofing and roof warranties. They’re specifically designed for low-slope roofs with materials like EPDM, TPO, or PVC. Before installation, an engineering assessment is necessary to ensure the roof structure can support the additional weight of the ballast system.

Do non-penetrating solar installations affect roof warranties?

Non-penetrating solar installations typically preserve roof warranties, which is one of their primary advantages. Traditional penetrating methods often void or complicate roof warranties due to the holes drilled into the roof surface. Methods like ballasted systems, metal roof clamps, and rail-less systems specifically designed to work with existing roofing materials allow homeowners to maintain manufacturer warranties while still enjoying the benefits of solar energy.